Custom Molding Services

Whether it’s blow, injection, or rotational molding, our expert Plastic injection molding manufacturers turn raw plastic materials into quality parts. Partnering with us means so much more than accessing advanced technology – it’s a commitment to innovation. Think about rivexa each time you require the expertise of a plastic injection molding company to bring your visions to life.

As your trusted contact for plastic injection molding companies, we understand decision and precision when it comes to your projects. When you choose rivexa to source from the best plastic injection molding manufacturers, you’re getting business partners invested in your success. Competitive pricing and an unwavering commitment to quality are what you get every time you choose from your vetted Plastic injection molding manufacturer.

500+

suppliers onboarded

7+ years

of average Export Experience

88%

Avg. Seller Response rate for quotations requests

6

Countries catered to, with many new locations coming soon..

100%

Verified Manufacturers

How it works

Material Selection

Choosing the kinds of plastic for your project needs based on flexibility, environmental, and durability considerations.

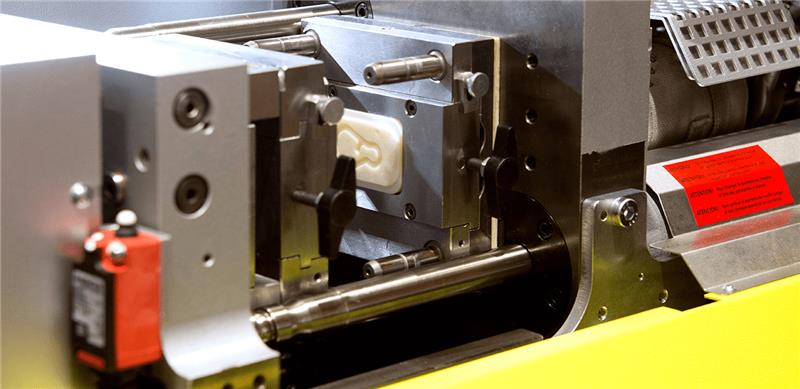

Mold Design

Choose suitable materials based on strength, durability, and compatibility with operating conditions.

Molding Process

Shape and refine components to precise dimensions using cutting, milling, and drilling techniques.

Cooling

Allow the molded part to cool and solidify, ensuring dimensional accuracy.

Demolding

Remove the finished plastic component from the mold.

Finishing

Perform necessary finishing operations such as trimming, painting, or polishing to achieve the final product.

Custom Molding Services Process Types

rivexa has verified suppliers across various custom molding services process types catering to all your sourcing needs..

Custom Molding Services FAQ